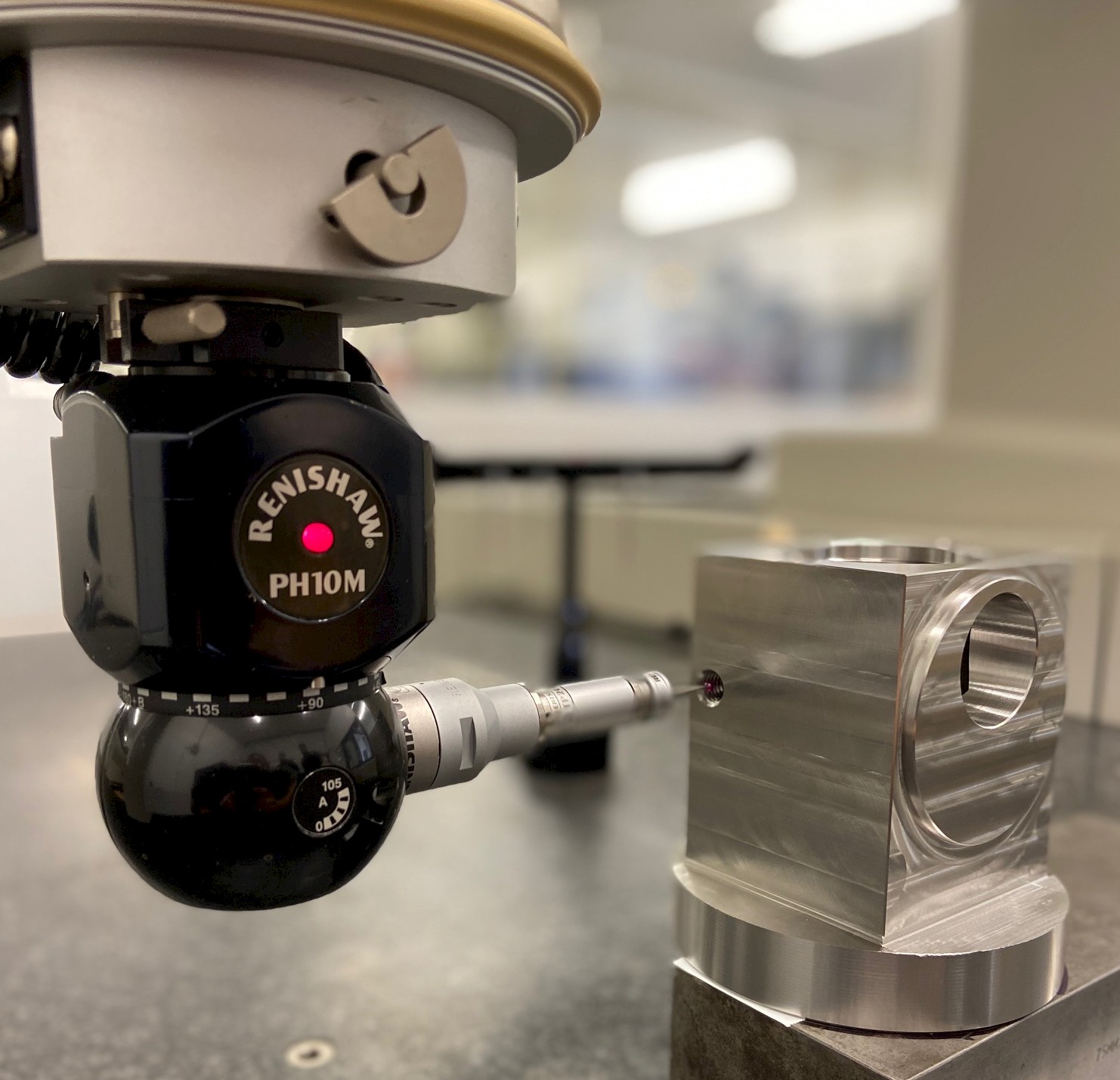

Quality & Inspection Services

Our quality department is equipped with Mitutoyo CMM systems and manual inspection instruments to perform full dimensional inspection and reporting. We offer stand‑alone inspection services and reverse engineering, and our design team can create drawings for legacy parts. We provide First Article Inspection Reports (F.A.I.R) and tailor data collection to customer requirements. With a fully traceable quality management system, we ensure your parts meet exacting standards. Contact us for CMM inspection or reverse engineering services.

CALL US TODAY

01233 668883