Precision Engineering & CNC Machining Services in Ashford

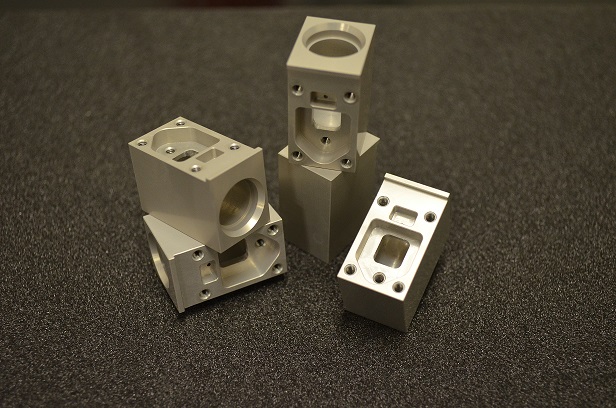

AES Precision Engineering We specialize in multi‑axis CNC milling, turning, sheet‑metal fabrication and inspection services. Our modern facility houses 3‑axis and 5‑axis machining centres, turn‑mill lathes and fabrication equipment to handle prototypes and high‑volume production. Industries we serve include medical, automotive, aerospace, defence, electronics and packaging. Our commitment to quality, on‑time delivery and continuous investment makes us the trusted partner for precision‑critical components.

CALL US TODAY

01233 668883